Unmatched Performance

Experience the superior performance of our plasma cutter, engineered for precision and power. Its innovative ‘blow-back’ start system ensures a remarkably smooth and interference-free engine initiation. This system is designed with safety in mind, minimizing risks to both operators and bystanders, while also preventing disruptions to nearby electrical equipment. This makes it ideal for various applications, from intricate metalwork to large-scale industrial projects.

Versatility and Wide Applications

This plasma cutter is exceptionally versatile. Its adaptability makes it a valuable tool for professionals and DIY enthusiasts alike. Whether you’re working on intricate metalwork, preparing for welding, tackling automotive repairs, or pursuing creative DIY art projects, this cutter delivers consistent, high-quality results. Its robust design and powerful capabilities make it a cornerstone for achieving reliable performance across a wide range of challenging applications.

Advanced Features for Superior Cutting

This plasma cutter boasts a substantial 55A high current for maximum power, enabling deeper cuts than many comparable models. The clean cut is impressive: 1/3″@110V, 1/2″@220V; max cut: 1/2″@110V, 4/5″@220V. The international leading MCU intelligent digital control technology ensures deep, precise, and clean cuts every time. A user-friendly digital display provides real-time feedback on crucial parameters such as air pressure, voltage, and current, allowing for timely adjustments and improved operational efficiency. An onboard error code system quickly identifies and displays potential machine problems.

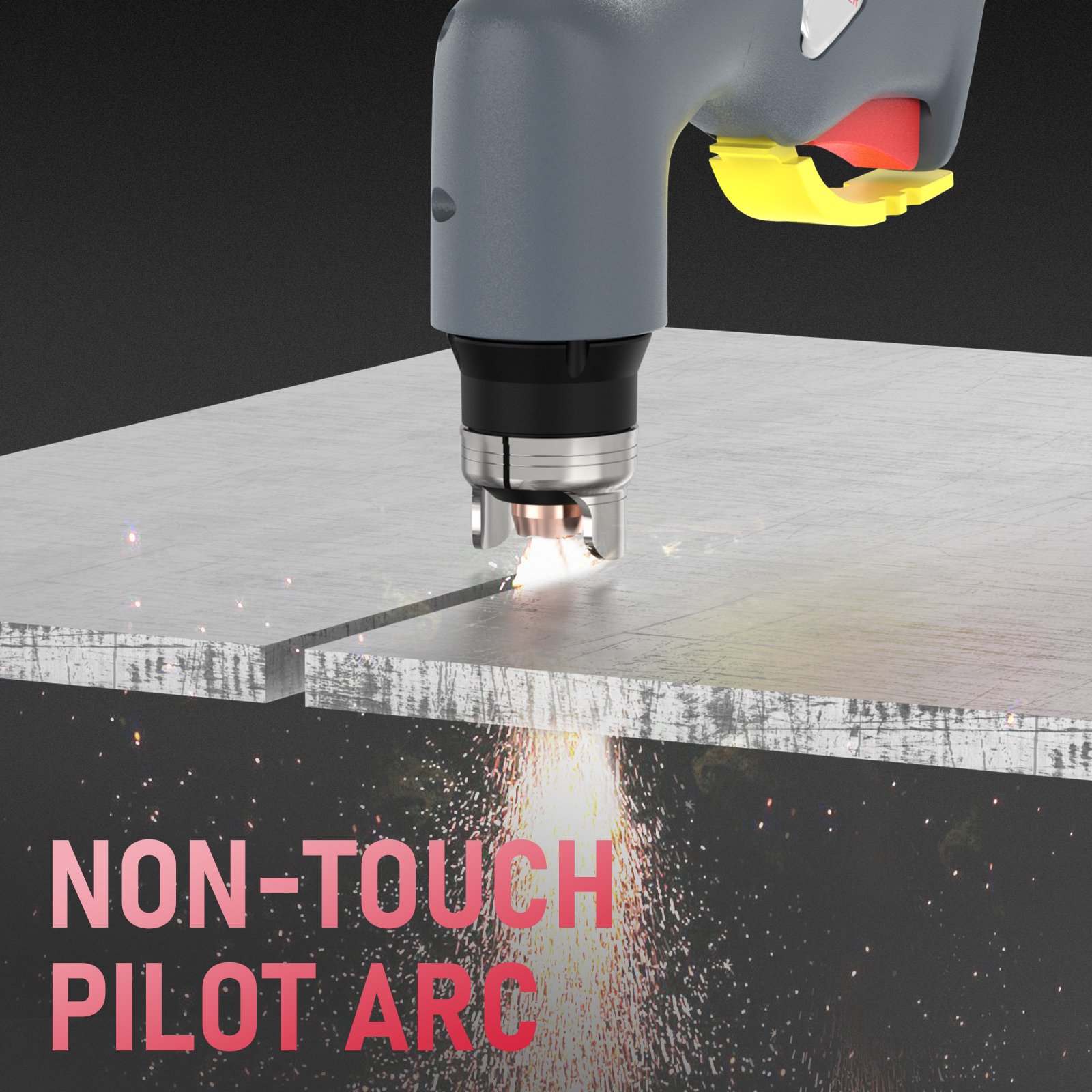

The included IPT40 torch further enhances performance. Its non-touch pilot arc technology allows for cutting without contacting the tips to the metal, resulting in superior cutting quality and extended consumable life. This is especially beneficial when working with rough, painted, or rusty surfaces. The PT/2T/4T function provides control over post-flow time (adjustable from 5-20 seconds), allowing you to fine-tune the cooling time of the welding head for optimal consumable life. We generally recommend a cooling time of 5-8 seconds. The 2T setting offers semi-automatic cutting control for precise cuts, while the 4T setting provides automatic control for long-term, continuous cutting operations.

Reviews

There are no reviews yet.